Coating thickness measurement in application at PHYNIX customers

Paint thickness measurement on car bodies

Application at FIAT Service Kühne

FIAT Service Kühne from Baesweiler, Germany, is a medium-sized, owner-managed car dealership. In addition to trading in new and used cars, its business also covers the repair of motor vehicles of all kinds and the sale of spare parts and accessories.

Buying and selling of used vehicles as well as the repair of accident damage often requires the measurement of paint thickness. It is important to detect repaint, fill work or to prove the correct paint thickness after repair.

The paint thickness gauge PaintCheck from PHYNIX in Neuss, Germany, is to answer these questions. This gauge is developed especially for the automotive industry. The measurement of the paint thickness takes place at the relevant points, fenders, hood and roof. The operation of the device is very simple: Switch on the device and put it on the body. The determined paint thickness is shown on the display, correct operation is always guaranteed.

Coating thickness measurement on enameled stainless steel sheets

Application at Werner & Pfleiderer Lebensmitteltechnik GmbH

As part of the WP BAKERYGROUP, Werner & Pfleiderer Lebensmitteltechnik GmbH in Dinkelsbühl, Germany, is one of the world's largest system providers for manual and industrial baking technology.

As a market leader, Werner & Pfleiderer Lebensmitteltechnik is committed to always incorporate the latest developments as standard in their ovens, machines and systems. For example, the well-proven shop baking oven MATADOR® STORE was recently also offered in a Color Edition with colored, enameled surfaces, in order to allow individual interior design concepts for shop baking.

Enameled stainless steel sheets are the best way to create a colorful surface, as they ensure a long-lasting finish that will withstand harsh environments. In order to meet the WP quality requirements, however, a minimum layer thickness is an absolute prerequisite. The strength of the enamel coating is therefore checked during the incoming goods inspection with a Coating Thickness Gauge Surfix® EX-FN from PHYNIX in Neuss, Germany. Equipped with a high-resolution color graphic display, this gauge measures layer thicknesses up to 1.5 mm on both steel and non-ferrous metals - ideal for measuring on non-magnetic stainless steel used in the MATADOR® STORE.

https://www.wp-l.de/produktwelt/komponenten/ladenbacken/matador-store-colour-edition.html

Coating thickness measurement from the air with drones

Application at U-ROB

The drones from the company U-ROB, Bielefeld, are used in many industries for the inspection of plants, piping, cooling towers, chimneys, etc. The revision of buildings or large machinery is facilitated by the use of drones. Meanwhile, drones are not only used for visual inspection with the help of cameras, but they are increasingly used as a device carrier to bring the necessary measuring equipment for specific tasks on site. Because of the outstanding flight characteristics and in addition to non-contact measurement methods, it is now also possible to use methods which require contact with the measurement object. As proof for these applications a coating thickness measuring device from the company PHYNIX from Neuss was mounted on a drone. It is now possible, to measure the corrosion protection of hard to reach objects, such as steel bridges, pylons, chimneys, pipelines, tank farms or wind turbines at low cost as the use of industrial climbers is avoided.

Conformal coating thickness measurement on circuit boards

Application at modus high-tech electronics GmbH

The company modus high-tech electronics GmbH from Willich has been a pioneer in the industry for decades in the development of fast scanner systems for industrial use. modus develops, produces and sells automatic optical test and inspection systems (AOI) for production monitoring in printed circuit board production.

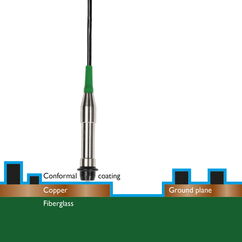

Newly produced and cleaned, populated circuit boards generally have good electrical characteristics. However, these can deteriorate quickly, particularly in the automotive sector, due to the influence of moisture or dirt. For this reason, the circuit boards nowadays are often provided with a protective lacquer after assembly to protect the sensitive circuits of the electronic assemblies against moisture (conformal coating, CC).

Automatic inspection with a modus CC AOI ensures that all painted assemblies can be checked quickly and thoroughly. UV particles mixed into the lacquer, which fluoresce using UV light, enable a clear varnish inspection in combination with multicolored LED lighting, UV LED lighting and a color line camera.

In order to make a statement about the paint thickness, a calibration is necessary. The brightness value of the camera image is correlated with the paint thickness actually measured at the same position. The resultant relationship between the image and the measured value is reflected in the color-coded image (Fig. 3).

A coating thickness gauge from PHYNIX is used to calibrate the modus CC AOI. modus decided for the top model from PHYNIX, the Surfix Pro X. This gauge shows all readings as well as the multilingual menu control on a high-resolution color graphic display. All readings are displayed and saved in the memory and can also be transferred to a computer via one of the interfaces (USB, Bluetooth). The Surfix Pro X can be connected to all probes from the PHYNIX probe range. Currently the standard probe FN1.5 is used, which works with the magnetic-inductive method according to DIN EN ISO 2178 and the eddy current method according to DIN EN ISO 2360.

For calibration, the probe is placed on a painted but component-free copper ground plane, and the paint thickness is measured there. Particularly advantageous are the small dimensions of the probe and its high measuring accuracy. The thickness values determined in this way are then used as input parameters for calibration of the optical coating thickness measurement.